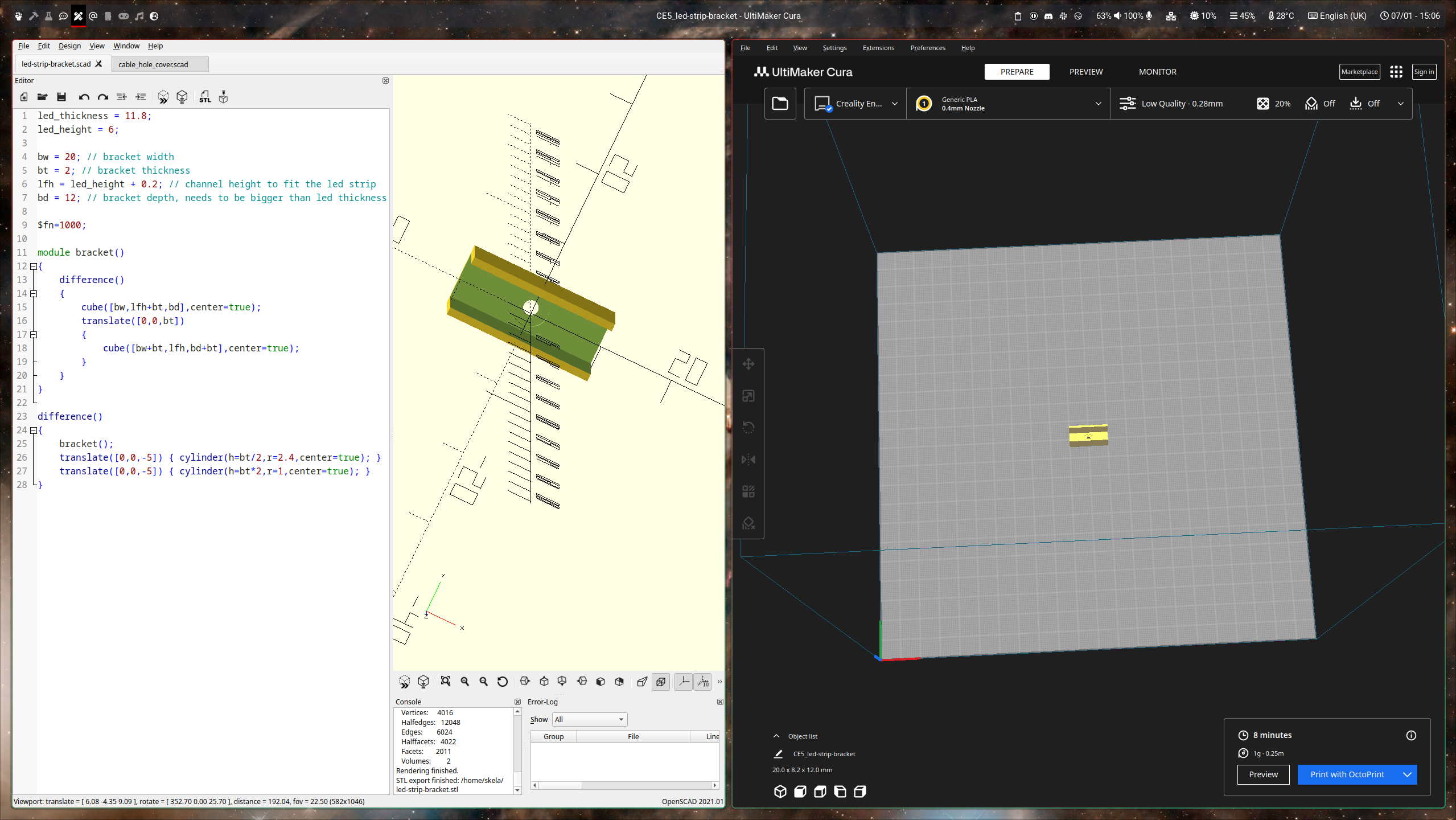

Needed a way to attach a LED strip I bought from AliExpress to an under-bed storage box. The dimensions of this particular strip were 11.8mm by 6mm. So OpenSCAD to the rescue. Made a simple cube, cut out a channel and added a screw hole.

Making a 3D Model

With OpenSCAD you can create 3D models using code, something I personally find much simpler than a graphical design tool. Its also a lot easier to adjust and modify these kinds of models, to fit other kinds of use-cases.

led_thickness = 11.8;

led_height = 6;

bw = 20; // bracket width

bt = 2; // bracket thickness

lfh = led_height + 0.2; // channel height to fit the led strip

bd = 12; // bracket depth, needs to be bigger than led thickness

$fn=1000;

module bracket()

{

difference()

{

cube([bw,lfh+bt,bd],center=true);

translate([0,0,bt])

{

cube([bw+bt,lfh,bd+bt],center=true);

}

}

}

difference()

{

bracket();

translate([0,0,-5]) { cylinder(h=bt/2,r=2.4,center=true); }

translate([0,0,-5]) { cylinder(h=bt*2,r=1,center=true); }

}

Exporting as an STL file

Once your happy with your design, you export it as an STL file, and then import that into the slicer / 3D printer software of your choice. Here I'm using UltiMaker Cura.

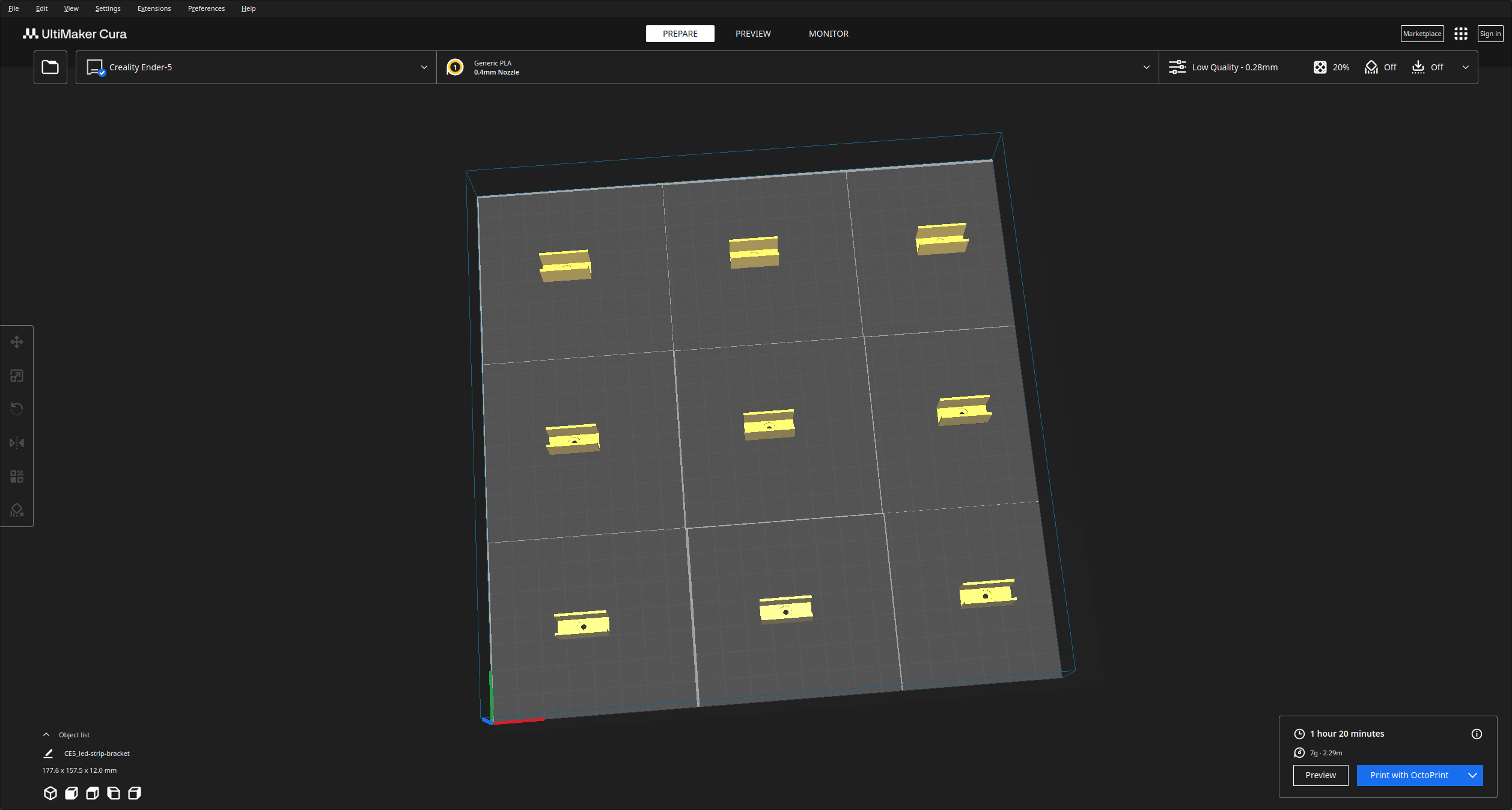

Sequential Prints

Printing a bunch of these would be a tad too tedious, if you had to do it 1 by 1. With UltiMaker Cura, you can set it to print sequentially. In this case, I was able to squeeze in 9 brackets every print, making the most of every square inch of my Ender 5 Pro build plate.

The End Result

Quite pleased with that, daughter approves.